We recommend you to use the following diagrams for a quick estimation of the consumption of welding consumables for welding ferritic steel butt joints and fillet joints respectively.

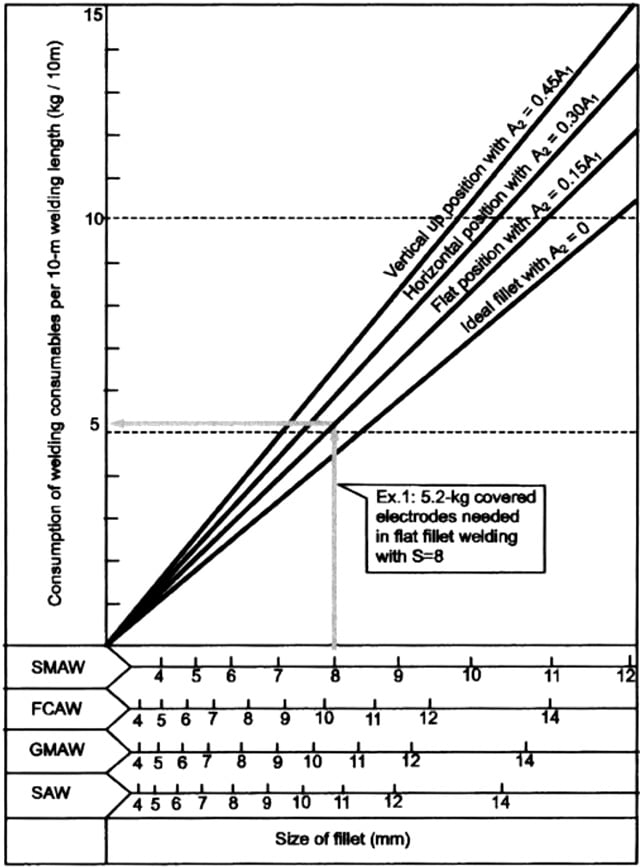

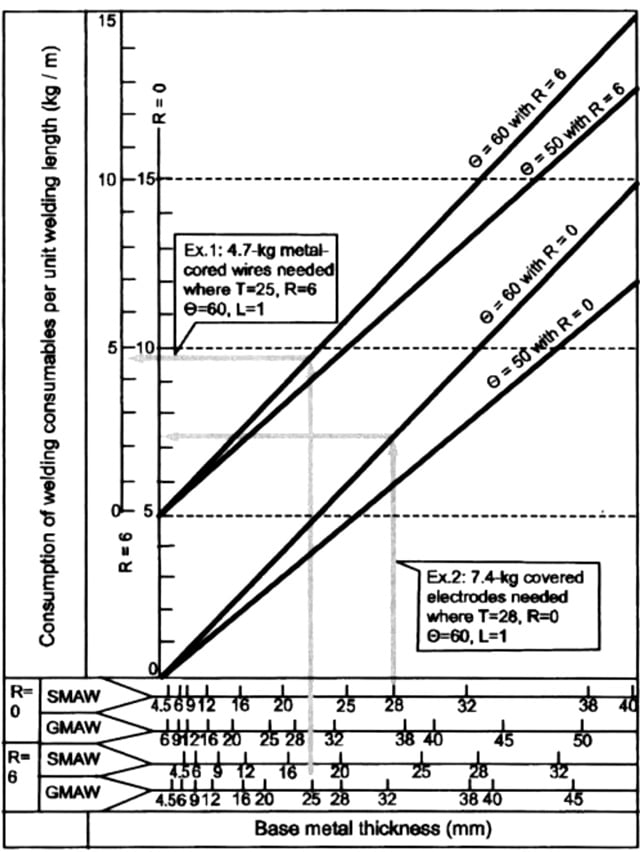

Please follow the examples indicated by gray arrows in the figures. Figure 2 shows the calculated consumption of welding consumables as a function of plate thickness, welding process, groove angle, and root opening for butt joints. With respect to fillet joints, Fig. 3 shows the calculated consumption of welding consumables as a function of fillet size, welding process, and reinforcement size. These diagrams were developed using the calculations obtained by the following equation for both groove and fillet welding joints under the prerequisites given below.

C = [(A1 + A2) x L x G/E] x 1/10

Where

C: Consumption of welding consumables (kg)

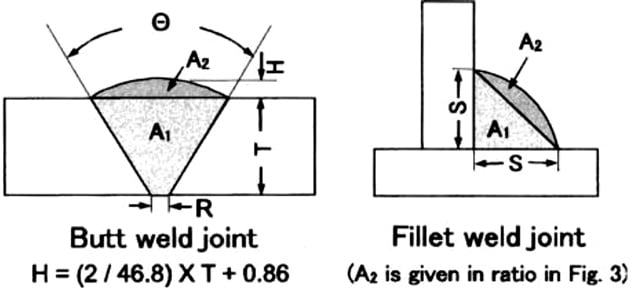

A1: Area of Section A1 weld metal (mm2) ― Fig. 1

A2: Area of Section A2 reinforcement (mm2) ― Fig. 1

L: Weld length (m)

G: Specific gravity of weld metal (7.85 g/cm3)

E: Deposition Efficiency (%) ―

SMAW covered electrodes: 55%

GMAW solid/metal-cored wires: 95%

FCAW flux-cored wires: 90%

SAW solid wires: 100%

Figure 1. Weld sizes (θ in deg., H, R, S and T in mm)

Figure 2. Consumption of covered electrodes in SMAW and solid/metal-cored wires in GMAW of butt joints